As organizations deepen their climate commitments, it becomes increasingly important to understand the full scope of emissions throughout the value chain. While many companies focus on direct operations or upstream supply chains, a crucial part of their environmental impact occurs after the sale—specifically when intermediate products are further processed into final goods. This blog explores Scope 3 Category 10, one of the more nuanced components of the GHG Protocol, which covers emissions from the processing of sold products by third parties. With regulatory scrutiny increasing and stakeholder expectations rising, understanding and addressing these downstream emissions is critical for credible sustainability reporting.

What is Scope 3 Category 10?

Scope 3 Category 10 includes GHG emissions from the transformation or processing of sold intermediate products by third-party entities before final use. These intermediate goods are not yet ready for end consumers and require further steps—such as manufacturing, cooking, refining, or assembly—by other companies to create a final product.

Examples include:

- A chemical company selling resin to a manufacturer that molds it into plastic products.

- A sugar supplier whose product is used in confectionery manufacturing.

- A metal processor selling sheets or ingots that are used in car assembly.

Unlike Scope 3 Category 11 (Use of Sold Products) or Category 12 (End-of-Life Treatment), Category 10 strictly pertains to processing activities that occur between sale and end use.

Why Does Category 10 Matter?

Understanding and reporting emissions from downstream processing offers a more accurate carbon footprint and delivers several business benefits:

1. Alignment with Leading Frameworks

Compliance with the GHG Protocol, CDP, and SBTi increasingly requires visibility into downstream activities. If your intermediate products undergo high-emission processing, this must be accounted for in sustainability disclosures.

2. Visibility into Lifecycle Impact

Downstream processing can contribute a significant share of lifecycle emissions, particularly in energy-intensive industries such as chemicals, metals, plastics, and textiles.

3. Competitive Advantage Through Transparency

Customers, investors, and regulators now expect companies to take shared responsibility for value chain emissions, not just those within operational control.

4. Product Innovation Opportunities

Understanding where downstream emissions occur can guide product redesign or material substitutions, reducing overall carbon intensity.

When Should You Report Scope 3 Category 10?

A company should report under Category 10 when:

- The product it sells is not final and requires further transformation.

- It has reasonable knowledge of how its product is processed.

- The processing activity is material to the company’s total Scope 3 emissions.

If the end use or downstream application is unknown or highly variable, guidance under Section 6.4 of the GHG Protocol recommends using assumptions or ranges based on industry data.

Challenges in Reporting Scope 3 Category 10 Emissions

Measuring emissions from the downstream processing of sold products is one of the more complex Scope 3 categories under the GHG Protocol. The nature of indirect responsibility, product variability, and data dependence on third parties makes accurate reporting a significant challenge.

1. Lack of Visibility into Downstream Processing

Most companies selling intermediate products do not have direct insight into how their customers use or process those products after sale. A single product may be:

- Processed using varied technologies with vastly different energy profiles,

- Combined with other raw materials whose emissions must be allocated, or

- Used in processes that span multiple stages before final assembly.

This lack of visibility makes it difficult to assign a single, reliable emission value to each product.

2. Limited Access to Customer Data

Gathering site-specific data from downstream customers requires trust, collaboration, and system integration—which many companies lack. Even where relationships are strong, customers may:

- Not collect the necessary data (e.g., fuel use, electricity consumption),

- Be unwilling to share proprietary processing information, or

- Lack the systems to report data in a standardized format.

This can force companies to rely on industry averages or outdated emission factors, reducing reporting accuracy.

3. Diverse Product Applications

Intermediate products can be transformed into many different end uses, each with its own processing emissions. For instance:

- A synthetic polymer might be processed into medical devices, automotive parts, or packaging—each with a different energy intensity.

- Agricultural commodities like sugar or soy may be refined into food products, cosmetics, or industrial chemicals.

This diversity makes emissions modeling extremely complex, especially when customer usage is not uniform or known.

4. Emission Allocation Complexities

When a product is used alongside other materials in a process (e.g., steel and rubber in car production), companies must determine:

- How much of the emissions from the process should be attributed to their product.

- Whether emissions should be calculated based on mass, economic value, or energy content.

This introduces ambiguity and potential double-counting or underreporting if not addressed carefully.

5. Inconsistent or Inadequate Emission Factors

Publicly available emission factors often focus on final products or upstream activities, with less clarity on midstream processing stages. For some sectors, robust LCA data or GHG emission factors may be:

- Outdated or regionalized,

- Nonexistent for certain processes,

- Inconsistent across different reporting standards.

This can lead to assumptions and estimations that affect the quality of the company’s sustainability disclosures.

Strategies to Reduce Scope 3 Category 10 Emissions

While companies may not control downstream processing directly, they can take proactive steps to influence, support, and reduce emissions associated with the use of their intermediate goods.

1. Collaborate with Downstream Customers

Building partnerships with customers can unlock valuable data and create joint opportunities for emissions reduction.

Action steps:

- Conduct customer emissions workshops to understand their processing footprints.

- Develop shared carbon reporting frameworks or integrate sustainability into contracts and service-level agreements.

- Offer technical support or digital tools to help customers improve their energy efficiency.

Example: A raw material supplier working with a packaging manufacturer to track emissions across molding, filling, and sealing processes, then jointly redesigning materials for lower energy consumption.

2. Design Products for Lower Processing Impact

The design of an intermediate product can significantly influence how energy- or resource-intensive its processing will be.

Key strategies:

- Select materials or compounds that require less heat, pressure, or water in processing.

- Eliminate additives or properties that increase processing time or waste generation.

- Use pre-processed or partially finished components to minimize work required by customers.

Example: A textile company developing pre-dyed fabrics that reduce the need for water- and energy-intensive dyeing at customer facilities.

3. Offer Low-Carbon or Verified Products

Many customers are seeking suppliers who can help them meet their own Scope 3 and SBTi targets.

Initiatives include:

- Launching product lines with verified product carbon footprints (PCFs).

- Highlighting low-emission variants using cleaner production or renewable inputs.

- Participating in product certification schemes (e.g., EPDs or CarbonNeutral products).

Example: A building materials company labeling its cement products with verified CO₂ footprints to help downstream users model and reduce emissions in construction.

4. Support Circular and Modular Product Designs

Encourage customers to adopt product architectures that reduce processing complexity.

Examples:

- Materials designed for easy disassembly or modular manufacturing.

- Components optimized for closed-loop recycling, requiring less intensive breakdown.

- Products that integrate multi-functionality, eliminating additional steps.

Sprih Insight: Circular product thinking not only reduces Scope 3 emissions but also drives innovation and resilience in your value chain.

5. Influence Behavior Through Procurement and Marketing

Use your position as a supplier to steer customers toward low-emission choices.

Approaches:

- Highlight the carbon impact difference between similar product SKUs.

- Include carbon metrics in digital catalogs and customer dashboards.

- Use differentiated pricing or incentives for customers choosing lower-emission options.

Sprih Advantage: Sprih’s product-level carbon tracking tools allow you to display embedded emissions data at the point of sale or proposal, influencing better downstream decisions.

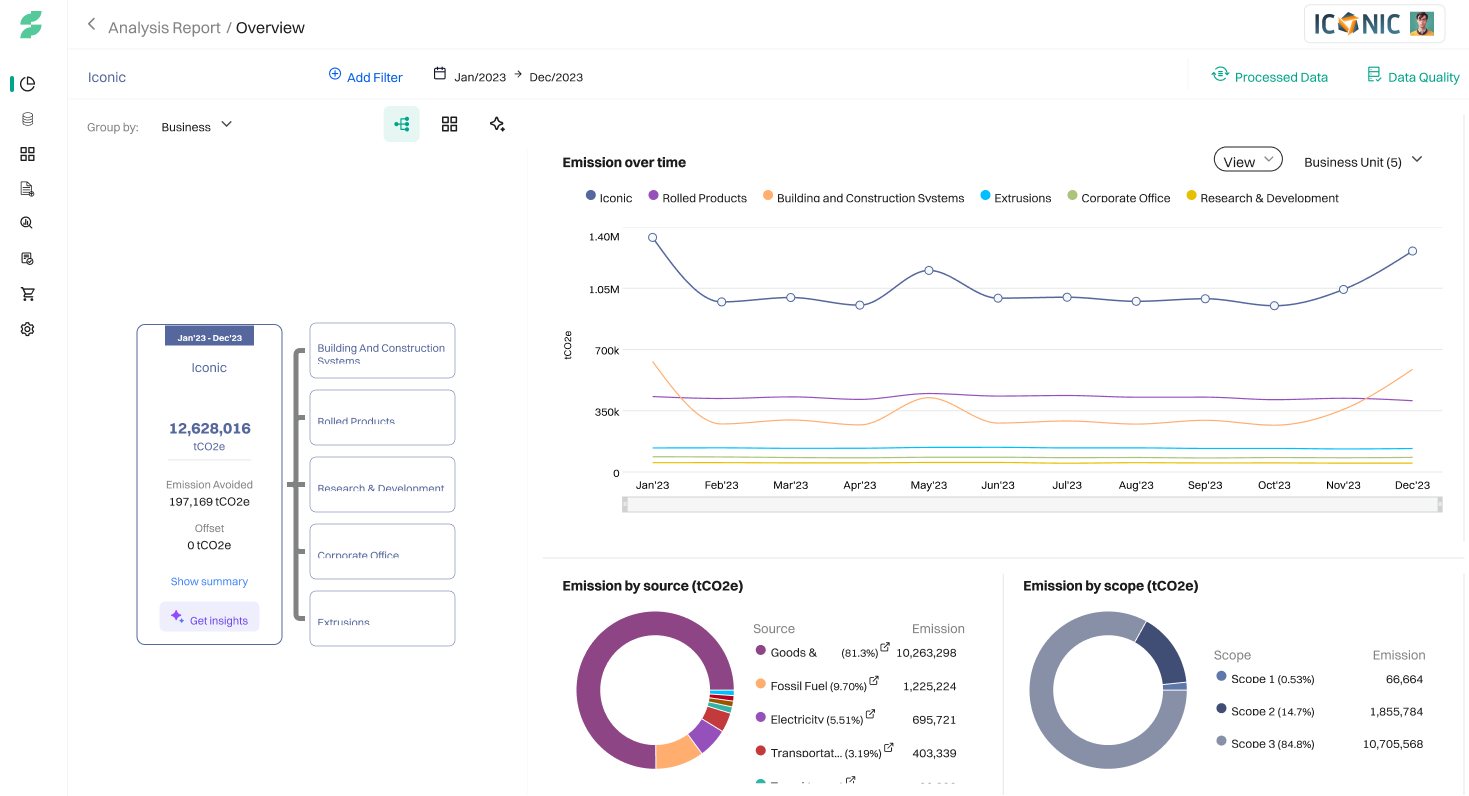

How Sprih Helps You Track and Reduce Scope 3 Category 10 Emissions

Sprih’s emissions platform offers powerful features tailored to Category 10 reporting:

- Integrated product-level carbon tracking

- Scenario modeling to assess carbon intensity of different processing pathways

- Automated data capture from ERP, CRM, and LCA systems

- Industry-specific emission factor libraries

- Audit-ready reports for CDP, GHG Protocol, and SBTi

Ready to simplify your Scope 3 carbon reporting?

Request a Demo and see how Sprih can help your business uncover and reduce emissions beyond the point of sale.

Take Responsibility Beyond the Sale

The climate impact of your products doesn’t stop when they leave your warehouse. Scope 3 Category 10 represents a vital opportunity to build transparency and take shared responsibility for your downstream value chain.

Whether you’re a materials manufacturer, chemical supplier, or energy-intensive producer, aligning with best practices in Category 10 will strengthen your sustainability strategy and support your net-zero ambitions.

Explore more with Sprih’s Sustainability Platform or speak with our experts to understand how to embed emissions tracking deep into your product lifecycle.

FAQs

What is Scope 3 Category 10?

Scope 3 Category 10 refers to greenhouse gas emissions resulting from the processing of sold intermediate products by third parties before they become final products.

When should a company report Scope 3 Category 10 emissions?

Reporting is appropriate when sold products require further processing, the company understands the processing methods, and these activities significantly contribute to total Scope 3 emissions.

How can companies calculate Scope 3 Category 10 emissions?

Companies can use a site-specific method by collecting data from downstream processors or an average-data method using industry benchmarks and emission factors.

Why is Scope 3 Category 10 significant in sustainability reporting?

It provides a more comprehensive view of a product’s lifecycle emissions, aiding in compliance with frameworks like the GHG Protocol, CDP, and SBTi.

What challenges exist in reporting Scope 3 Category 10 emissions?

Challenges include limited visibility into downstream processes, variability in processing methods, and reliance on data from third-party entities.